Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Understand the core technologies behind advanced manufacturing, including automation, robotics, and AI-driven processes.

In the era of rapid technological advancement, the manufacturing sector has seen a significant transformation, giving rise to the concept of advanced manufacturing. This term encompasses a wide range of innovative processes and technologies that enhance productivity, efficiency, and flexibility in the production of goods. As industries increasingly seek to optimize their operations, understanding advanced manufacturing’s key technologies and emerging trends becomes essential for businesses aiming to maintain competitiveness in a global market.

Advanced manufacturing goes beyond traditional manufacturing practices by integrating cutting-edge technologies and novel approaches to production. According to the National Institute of Standards and Technology (NIST), advanced manufacturing refers to the use of innovative technology to improve products and processes. This includes but is not limited to automation, data analytics, artificial intelligence (AI), and advanced materials.

Additive manufacturing, commonly known as 3D printing, is one of the cornerstone technologies of advanced manufacturing. It allows for the creation of complex geometries and customized products with minimal waste. Industries such as aerospace, healthcare, and automotive rapidly adopt this technology for prototyping and production. Recent advancements have enabled the use of metal and biocompatible materials, expanding its applications further.

The Internet of Things has revolutionized manufacturing by connecting machinery, tools, and systems through the internet. This connectivity enables real-time monitoring and data collection, leading to improved operational efficiencies. Forbes notes that IoT helps manufacturers predict equipment failures, optimize maintenance schedules, and enhance supply chain management.

AI and machine learning have emerged as essential tools within advanced manufacturing. These technologies analyze vast data sets to provide insights that drive decision-making. From predictive analytics to automated quality control, AI helps manufacturers increase efficiency and reduce costs. For example, AI algorithms can identify patterns in production data, allowing for proactive measures to enhance quality and minimize downtime.

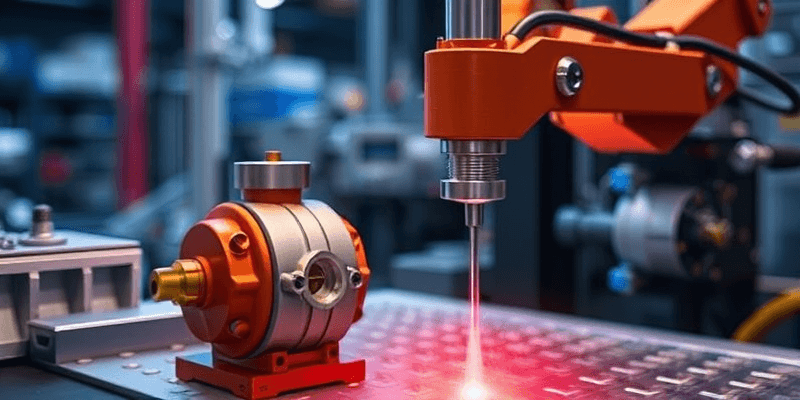

Robots are increasingly utilized in advanced manufacturing to perform tasks that are repetitive, dangerous, or require high precision. Innovations in robotics technologies, such as collaborative robots (cobots), have made it easier for human workers and machines to coexist on the production floor. These robots can be programmed to learn and adapt to new tasks, offering greater flexibility in manufacturing processes.

The development of advanced materials, including lightweight composites and biomaterials, is critical for modern manufacturing. These materials exhibit superior properties, such as increased durability, improved performance, and reduced environmental impact. Innovations in materials science continue to drive advancements in sectors like aerospace, automotive, and electronics, where performance and sustainability are paramount.

Digital twin technology creates a virtual representation of physical assets or processes. This allows manufacturers to simulate production scenarios, monitor performance in real-time, and optimize operations. By employing digital twins, companies can anticipate potential issues and reduce the risk of costly downtime. Gartner describes this technology as having transformative potential across various manufacturing sectors.

Sustainability is becoming a vital focus in advanced manufacturing. Companies are increasingly adopting “green” practices to reduce waste, lower energy consumption, and minimize their carbon footprint. This trend not only benefits the environment but also meets the growing consumer demand for sustainable products. Many manufacturers are investing in renewable energy sources and re-engineering supply chains to enhance sustainability efforts.

Flexible and agile manufacturing systems are designed to quickly adapt to changing market demands. With the integration of advanced technologies, manufacturers can shift production lines with minimal downtime. This ability to be agile is crucial in today’s fast-paced market, where consumer preferences can shift rapidly. Companies that can respond quickly to market changes ultimately gain a competitive advantage.

As manufacturing becomes more connected through IoT and digitization, cybersecurity has emerged as a pressing concern. Protecting sensitive data and production processes from cyber threats is essential for maintaining operational integrity. Manufacturers are investing in advanced cybersecurity measures to safeguard against potential breaches, ensuring the security of their assets and systems.

Advanced manufacturing represents a paradigm shift in how products are designed, produced, and delivered. By harnessing key technologies such as additive manufacturing, IoT, AI, and robotics, manufacturers are revolutionizing their operations, improving efficiency, and responding rapidly to market demands. As emerging trends like digital twins and sustainability continue to shape the manufacturing landscape, businesses must embrace these changes to remain competitive in an ever-evolving global marketplace.