Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

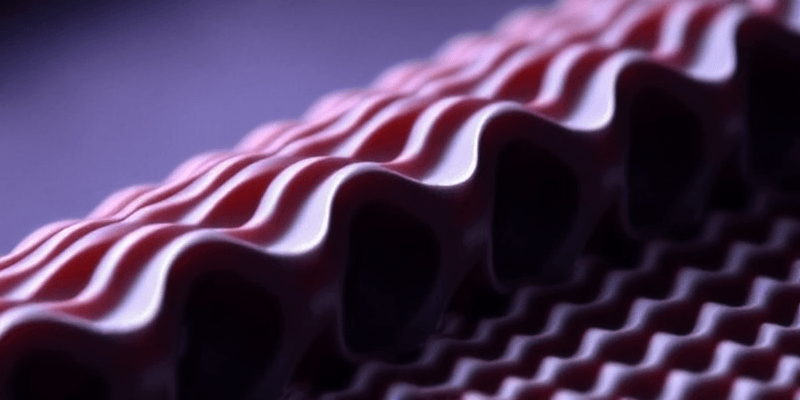

In recent decades, advanced composite materials have revolutionized various industries, from aerospace to automotive, thanks to their exceptional mechanical properties and lightweight nature. Composites made from a combination of materials, such as carbon fibers or aramid fibers embedded in a polymer matrix, offer an innovative solution to the challenges of modern engineering. This blog explores the science behind advanced composite materials, elucidating key insights into their structure, properties, and applications.

Composite materials are formed by combining two or more distinct materials to achieve superior properties not found in individual components. The two primary constituents of a composite are:

The microstructure of composites allows for tunable properties, enabling engineers to design materials that meet specific performance criteria. The interactions between the matrix and the reinforcement are crucial in determining the overall characteristics of the composite.

One of the standout features of advanced composite materials is their excellent mechanical performance, characterized by high tensile strength, low density, and superior fatigue resistance. The Journal of Materials Science highlights how composites can be engineered to absorb impact energy efficiently while maintaining structural integrity.

Unlike traditional materials like metals, composites can be tailored to exhibit anisotropic properties, meaning their strength can vary in different directions. This adaptability makes them ideal for applications where directional strength is crucial, such as in aircraft wings and automotive body panels.

The manufacturing processes for advanced composites have evolved significantly, with methods such as vacuum-assisted resin transfer molding (VARTM), autoclave processing, and 3D printing being widely adopted. These techniques not only improve material consistency but also enhance the production efficiency.

For instance, CompositesWorld discusses how 3D printing has opened new avenues for complex geometries that were previously unattainable, allowing for on-demand production and customized solutions.

Advanced composites are employed across various sectors due to their versatility and performance advantages. In aerospace, they are used to manufacture lightweight structures that reduce fuel consumption. The automotive industry leverages these materials to improve fuel efficiency and enhance safety without compromising performance.

Furthermore, the renewable energy sector utilizes advanced composites in wind turbine blades, where their high strength-to-weight ratio contributes to increased efficiency and sustainability. According to a study published in the Springer Series on Composite Materials, the integration of composites into energy systems is pivotal for meeting global sustainability goals.

Despite their advantages, advanced composite materials face challenges, particularly concerning recycling and environmental impact. As industries move toward sustainability, developing methods for effective recycling and reuse of composites is vital. Innovations in bio-based composites and enhanced recycling techniques hold promise for addressing these challenges.

The ongoing research into smart composite materials, which can self-repair and change their properties in response to environmental stimuli, represents the cutting edge of this field. As outlined in the Frontiers in Materials, the future of advanced composites will likely be driven by these innovative solutions that will further expand their applications and enhance their sustainability.

The science behind advanced composite materials is a fascinating interplay of material properties, engineering design, and innovative manufacturing techniques. As industries continue to demand materials that are lighter, stronger, and more efficient, the advancements in composite technology will play a crucial role in meeting these needs. The ongoing research and development in this field promise exciting possibilities, paving the way for enhanced performance and sustainability in a wide array of applications.