Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

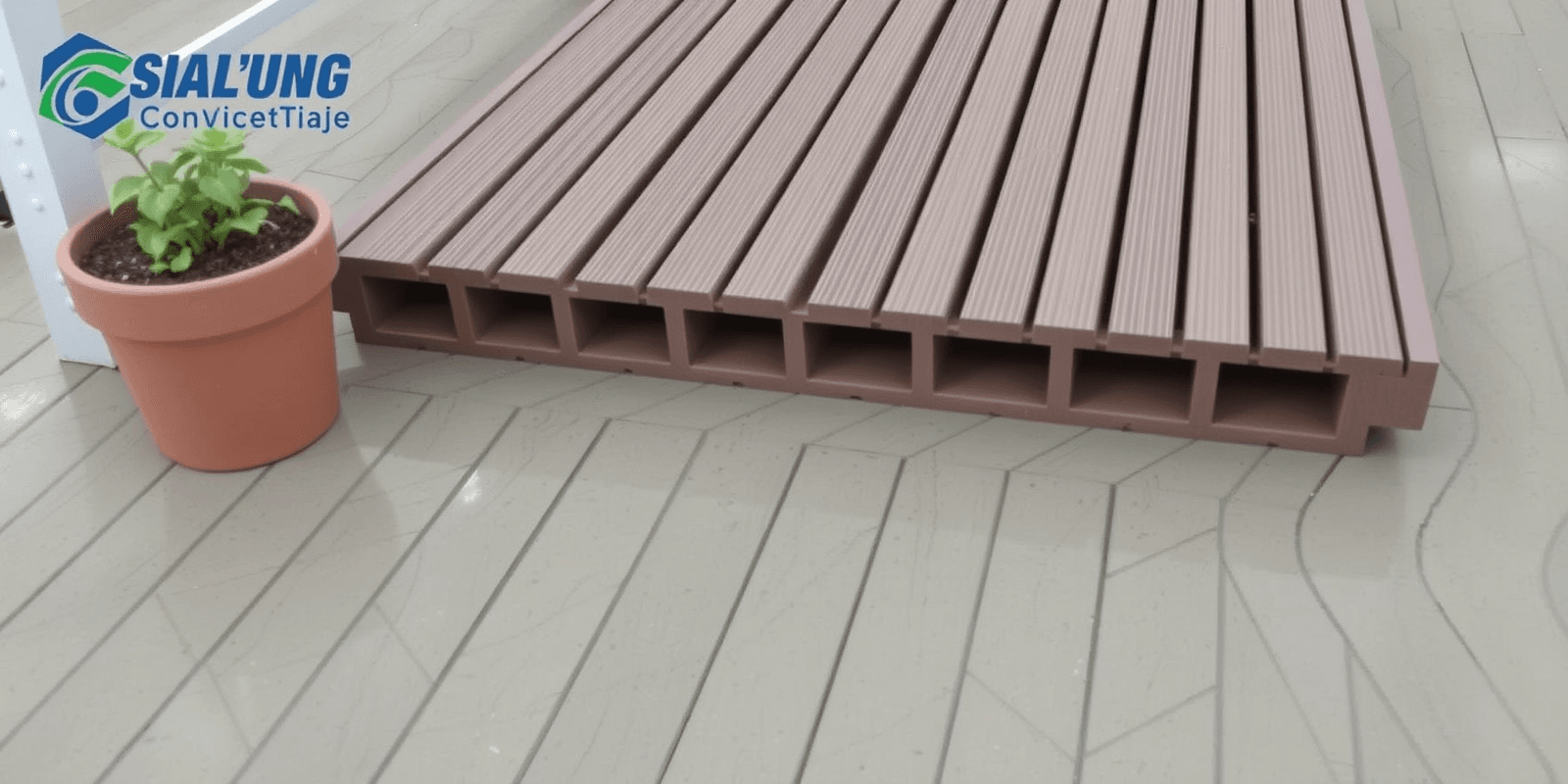

In recent years, the construction industry has seen a significant shift towards sustainable and cost-effective building materials. One such material that has gained popularity is Wood Plastic Composite (WPC) hollow decking. These decks are not only environmentally friendly but also offer substantial economic benefits for both homeowners and commercial builders. In this article, we will explore how purchasing WPC hollow decking from wholesale normal wpc hollow decking factories can reduce construction costs and improve overall project efficiency.

The adoption of WPC hollow decking in construction projects offers numerous economic advantages. The primary benefit is the reduction in labor costs. WPC hollow decking is significantly lighter than traditional wooden decks, making it easier to handle and install. This ease of installation translates into faster construction times and reduced labor expenses.

Another key advantage is the lower maintenance requirements of WPC hollow decking over time. Unlike traditional wood, WPC does not require regular painting, staining, or sealing. It is also resistant to moisture, rot, and insect damage, which means less frequent repairs and replacements. As a result, property owners can save money on maintenance costs in the long run.

The lightweight nature of WPC hollow decking makes it an ideal choice for large-scale construction projects. The material’s low weight reduces the need for heavy machinery during installation, which in turn lowers labor costs. Additionally, the straightforward installation process requires fewer skilled workers, further reducing labor expenses.

For instance, a large commercial project in New York City utilized WPC hollow decking from a reputable wholesale normal wpc hollow decking factory. The project manager reported a 20% reduction in labor costs compared to using traditional wooden decking. The ease of installation allowed the team to complete the project ahead of schedule, resulting in additional cost savings.

Maintaining a deck over its lifetime can be a costly endeavor, especially when dealing with traditional wooden materials. However, WPC hollow decking offers a durable and low-maintenance alternative. The material’s resistance to moisture, rot, and insects ensures that it remains in good condition for many years without requiring extensive upkeep.

A homeowner in California installed a WPC hollow deck on their backyard patio two years ago. They have since noted that the deck requires minimal maintenance compared to their previous wooden deck. “We haven’t had to do any major repairs or touch-ups,” said Sarah Johnson, the homeowner. “The deck looks as good as new, and we’ve saved a lot of money on maintenance.”

While the upfront cost of WPC hollow decking may be slightly higher than traditional wooden decks, the long-term savings are considerable. The durability and longevity of WPC mean that property owners do not need to replace the deck as frequently, leading to significant cost savings over time.

A study conducted by the National Institute of Standards and Technology (NIST) found that WPC decks have a longer lifespan than traditional wooden decks, with some lasting up to 25 years without major repairs. This extended lifespan translates into substantial cost savings for homeowners and commercial builders alike.

To illustrate the economic benefits of WPC hollow decking, let us consider a few case studies and testimonials from satisfied customers.

Case Study: Residential Deck Project

John and Mary Thompson, residents of Florida, recently replaced their old wooden deck with a WPC hollow deck. According to John, “The initial cost was higher, but the savings in labor and maintenance have been significant. We no longer have to worry about constant repairs and replacements.”

Testimonial: Commercial Building Project

Alex Johnson, a project manager for a commercial construction firm in Texas, shared his experience with WPC hollow decking. “We used WPC hollow decking on a recent project, and it was a game-changer. The lightweight material made installation much easier, and the reduced maintenance requirements have saved us thousands of dollars.”

Wholesale normal wpc hollow decking factories offer a cost-effective solution for construction projects. By reducing labor costs through lightweight and easy-to-install materials, lowering maintenance requirements, and providing long-term savings compared to traditional wooden decks, WPC hollow decking presents a compelling economic proposition for both homeowners and commercial builders.

As more projects adopt WPC hollow decking, the construction industry will continue to see the economic benefits of this sustainable and efficient building material. Whether you’re planning a residential deck or a large commercial project, investing in WPC hollow decking from a reputable wholesale factory can lead to significant cost savings and improved project outcomes.

National Institute of Standards and Technology (NIST). (2022). Lifespan Analysis of Decking Materials.

New York City Construction Industry Report. (2021). Economic Impact of Sustainable Building Materials.