Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

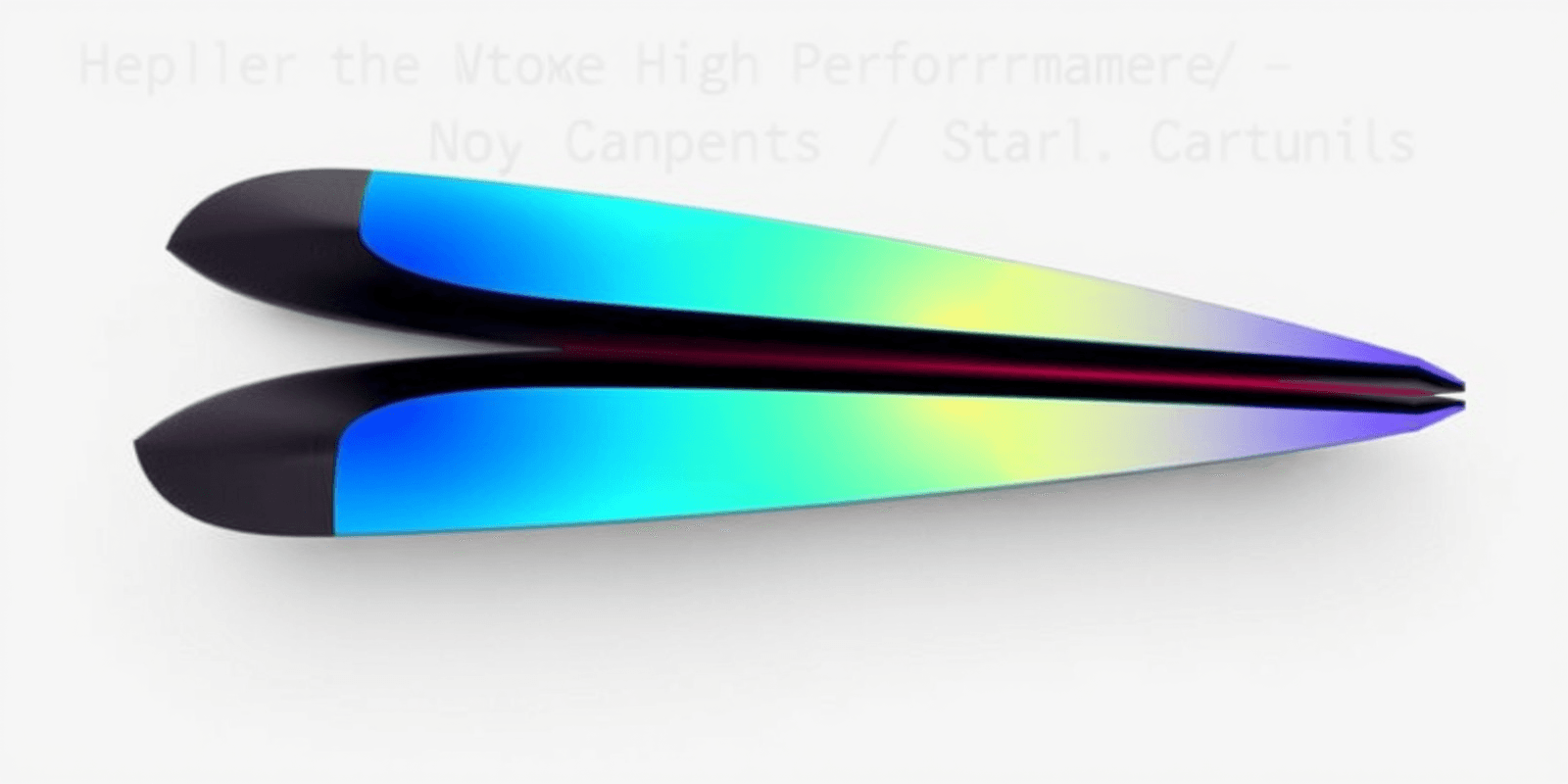

Discover the revolutionary advancements in high-performance composite materials and their applications across various industries, including aerospace, automotive, and sports equipment.

High-performance composite materials have emerged as a game-changing solution across various industries, offering unique characteristics that pave the way for significant technological advancements and enhanced sustainability. This article delves into the essential attributes, benefits, and emerging trends in high-performance composite materials, while also showcasing real-world applications and the profound impact these materials have on our future.

In a world increasingly driven by innovation, high-performance composite materials represent a critical development across fields such as aerospace, automotive, construction, and sports equipment. These materials, composed of two or more constituent materials that, when combined, produce unique physical and chemical properties, have seized attention due to their lightweight nature, high strength-to-weight ratios, and exceptional resistance to environmental factors.

The demand for more efficient, durable, and sustainable materials continues to rise, and high-performance composites are adeptly addressing these requirements. With the ongoing research and development efforts, we are on the cusp of realizing their full potential. This article aims to explore the defining characteristics of high-performance composite materials, the benefits they offer, current trends in their development and application, and their positive implications for sustainability.

High-performance composite materials exhibit several distinctive characteristics that differentiate them from traditional materials such as metals and plastics. These key properties include:

One of the most attractive features of high-performance composite materials is their weight advantage. They often possess a high strength-to-weight ratio, making them ideal for applications where weight savings are critical, such as in the aerospace and automotive industries. For example, carbon fiber reinforced polymers are known to be five times stronger than steel yet significantly lighter, allowing for greater fuel efficiency and performance in vehicles.

High-performance composites are engineered to withstand harsh environmental conditions. Their resistance to extreme temperatures, corrosive chemicals, and moisture contributes to their longevity and reliability in various applications. For instance, composite materials used in marine environments can resist saltwater corrosion, thereby enhancing the lifespan of vessels and structures.

Composite materials can be tailored to achieve specific functional and structural performance characteristics. By manipulating the matrix and reinforcement types, manufacturers can design composites that meet precise requirements, whether it be flexibility, rigidity, or thermal stability. This versatility makes them suitable for a wide range of applications across industries.

High-performance composites can be produced in various colors and finishes, offering aesthetic advantages. This quality is particularly beneficial in consumer goods and design applications where visual appeal is crucial. Manufacturers can create sleek designs without compromising performance.

The advantages presented by high-performance composite materials extend beyond their intrinsic properties, positively impacting manufacturers, consumers, and the environment alike.

By integrating high-performance composites into their products, manufacturers can achieve significant enhancements in performance. For example, in the aerospace sector, lightweight composite materials have enabled the creation of aircraft that consume less fuel, which ultimately leads to reduced operational costs and lower emissions.

While the initial investment in high-performance composite materials can be higher than traditional materials, their long-term benefits—such as durability and lower maintenance costs—can result in overall cost savings. Manufacturers and end-users alike can save money through fewer repairs and replacements.

One of the most compelling reasons for embracing high-performance composite materials is their potential for promoting sustainability. These materials can contribute to energy savings by enabling lightweight designs that improve fuel efficiency in transportation. Additionally, the lifecycle of composites can be optimized through recycling and reuse initiatives, mitigating some of the environmental impacts associated with conventional materials.

As the demand for high-performance composite materials continues to surge, several emerging trends are shaping their development and application:

Advancements in manufacturing technologies, such as additive manufacturing and automated fiber placement, have created opportunities for producing complex composite structures with greater consistency and reduced waste. These innovations enhance production efficiency and minimize operational costs for manufacturers.

With a growing emphasis on sustainability, there is an increasing trend towards the development of bio-based composite materials derived from renewable sources. These materials aim to reduce dependency on fossil fuels while maintaining the high-performance characteristics expected from composites. Research is underway in utilizing plant fibers, bio-resins, and other sustainable materials to create environmentally friendly composites with competitive performance properties.

High-performance composite materials are increasingly being integrated with smart technologies, creating interactive and adaptive materials. Sensors embedded within composites can facilitate real-time monitoring of structural integrity, leading to enhanced safety measures in applications such as aerospace and civil engineering.

The rise of electric and autonomous vehicles has spurred interest in high-performance composite materials, particularly due to their lightweight benefits. As manufacturers seek to improve battery efficiency and driving range, composites are poised to play a crucial role in vehicle design and manufacturing.

The versatility and performance of high-performance composite materials lend themselves to an array of applications across various sectors:

The aerospace industry extensively utilizes high-performance composites for structures such as fuselages, wings, and internal components. Composites provide the necessary strength and weight savings, contributing to improved fuel efficiency and performance metrics. Major manufacturers like Boeing and Airbus are leading the way in adopting composite materials in their aircraft designs.

In the automotive sector, high-performance composites are gaining traction with the increasing demand for electric vehicles. Components such as body panels, chassis, and interior elements are now often composed of composites aimed at reducing weight and improving energy efficiency. Companies like Tesla embrace composite materials to enhance vehicle performance and sustainability.

The construction industry leverages high-performance composites for applications such as bridges, marine structures, and high-rise buildings. Composites offer excellent durability and resistance to weather-related wear, thus extending the life of structures while reducing maintenance costs.

High-performance composites are also prevalent in the sports and recreation sector. Equipment ranging from bicycles to golf clubs incorporates composite materials to enhance performance. The combination of lightweight and strength allows athletes to achieve higher performance levels, giving them a competitive edge.

The impact of high-performance composite materials extends beyond individual industries, shaping broader technological advancements and sustainable practices. The incorporation of composites allows for innovation in creating lighter, stronger, and more efficient products. Furthermore, with growing environmental concerns, the move toward sustainable practices fosters a culture of responsibility across sectors.

High-performance composite materials are poised to play a vital role in addressing the dual challenges of technological advancement and environmental sustainability. Their unique properties allow for innovative designs that not only perform better but also align with global sustainability goals, making them an essential component of the future landscape.

As we explore the future of high-performance composite materials, it becomes clear that their distinctive characteristics, benefits, and emerging trends hold immense potential for various industries. With their lightweight, strength, durability, and customization capabilities, high-performance composites are not only transforming traditional manufacturing processes but also guiding us towards more sustainable practices. As the advancements in technology continue, the role of high-performance composite materials will undoubtedly expand, solidifying their importance in the pursuit of a sustainable and innovative future.